Rumblestrip Collaborates with PDC

Andreas Persson, Rumblestrip

With increasing fuel prices and environmental awareness, it is very clear that the heavy transport industry needs to continuously improve the fuel effciency of its trucks. Aerodynamic drag is one of the biggest contributors to total fuel consumption, so manufacturers spend many millions each year on developing the aerodynamic properties of their vehicles, which must live up to ever tighter regulations regarding emissions.

The roof air deflector, which sits on top of the cab roof, is the single most important component for reducing air resistance – provided it is adjusted correctly with regard to the trailer height and gap. Sadly, many trucks, in reality, drive around with incorrectly adjusted roof deflectors. The result is that haulers on average unnecessarily waste several percent of their fuel. In the worst cases, the penalty can be in excess of 10 %. This is significant in an industry where every fraction of a percent in reduced fuel consumption is chased by the engineers!

Rumblestrip was founded in 2016 with a clear focus on developing more intelligent solutions, which make sure that the trucks on our roads achieve the lowest possible fuel consumption, while maintaining ease-of-use for the driver. Its first product - Ecosense Trailer Assist - is a fully automatic roof air deflector system that makes sure that the deflector is always set in the optimal position, without any user-input being necessary.

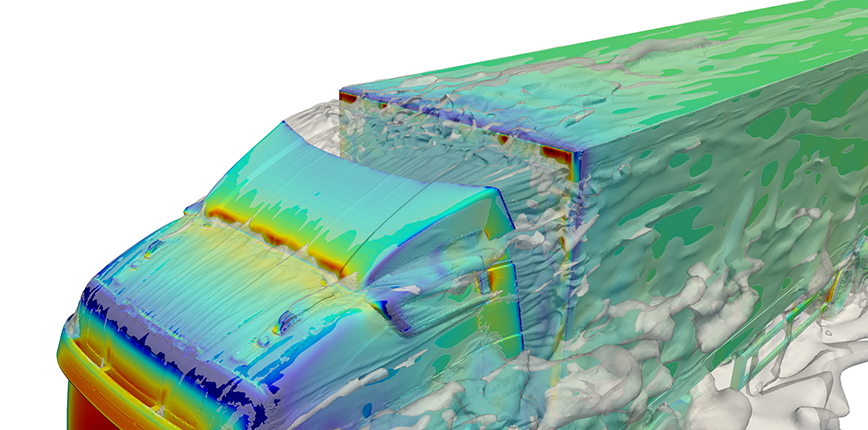

The core of the product is software that analyses the configuration of the truck as well as the aerodynamic flow field, and positions the deflector optimally at all times. To fully understand the behaviour of the flow field around different types of trucks and deflector settings, a large number of computational fluid dynamics (CFD) simulations are performed on the Beskow cluster at PDC.

A key goal of these simulations is to understand how the forces on the deflector vary with its angle, and how these relate to the drag value of the vehicle. Rumblestrip uses an almost fully-automated OpenFOAM process, from meshing on the computation nodes (snappyHexMesh) to postprocessing on Beskow or Tegner. A typical mesh size is in the region of 30-50 million cells, and a full Reynolds- averaged Navier-Stokes (RANS) simulation can be completed in only 4-5 hours on 128 cores.

Having access to the PDC supercomputers is a great asset for a young start-up company like Rumblestrip. Primarily, it makes virtually infinite scaling possible if there is a tight deadline. Compared to other high performance computing (HPC) solutions that Rumblestrip has tested, the main advantages of working with PDC are the raw performance, scalability, and excellent support, all of which make PDC a very compelling partner for Rumblestrip.