KTH teachers are cutting out templates for local apron factory´s protective suits

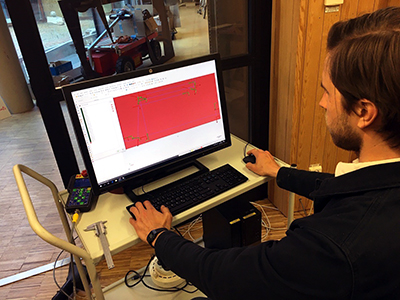

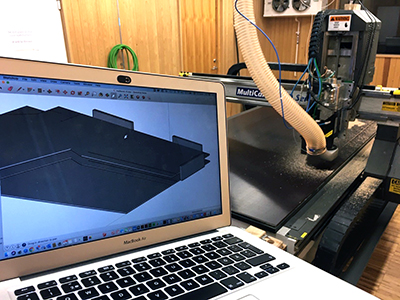

On Friday, May 8, the activity was in full swing at the Architecture School's makerspace workshop Verkstaden at KTH Royal Institute of Technology. Two teachers were producing templates with a CNC milling machine for the local Stockholm non-profit organization Förklädesfabriken (The Apron Factory). Förklädesfabriken is now using the templates in the production of protective aprons for elderly care service centres.

Not only is there a shortage of protective suits during the corona crisis, but templates for the production of the suits are also lacking. This is something that Per Franson , teacher of architecture at KTH Royal Institute of Technology, became aware of a few weeks ago, when he joined in as a volunteer at Förklädesfabriken (The Apron Factory), a non-profit, local pop-up factory in Stockholm for production of protective equipment for the elderly care service centres.

“I was there cutting and welding, ” Franson says. “And Jan Rydén , who works at Förklädesfabriken and who also is a research engineer here at the School of Architecture and the Built Environment, asked me about our maker space Verkstaden and what we can do there in order to help out in this situation”, he says.

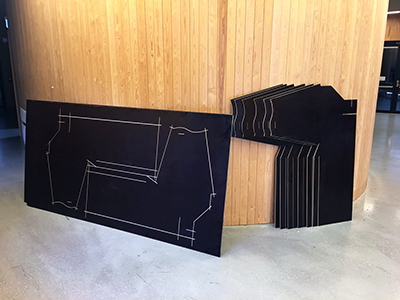

They also make templates for tabletops for the cutting tables

Together with one of his colleagues, Franson produced a half a dozen templates, using the School of Architecture and the Built Environment´s CNC milling machine. As template model, they used a CAD (Computer-aided design) file from Förklädesfabriken. Before production could begin in the Verkstaden makerspace, Franson and his colleagues needed to do a little tweaking to the CAD file, with regards to the depth of the cuts.

“It´s important that the templates make the cutting of the aprons run easy and smooth. However, it´s equally important that they hold for wear. I believe the pattern we are using comes from a doctor who had cut up his own protective clothes, “ Franson says. “The protective film that is cut out only has to be welded together in the sleeves”.

Förklädesfabriken is run by volunteers

Franson and his colleague delivered the templates to Förklädesfabriken Friday afternoon last week and the templates are now in full use at the factory.

“We now have two cutting tables of the new design up and running. The templates are sufficient for our needs, but they wear out quickly, “ says Jan Rydén at Förklädesfabriken.

Förklädesfabriken started out during the Easter holidays on the initiative of siblings Jens Peterson Berger and Lisa Peterson Berger. Within just a couple of days they had set up a pop-up factory in an empty dance hall in Farsta in South Stockholm and started delivering protective aprons to local elderly care service centres. Förklädesfabriken now consists of about ten people who run the activities. Everyday around 100 volunteers help out with the production.

“The work everyone is doing is completely non-profit and everything is funded through donations. Everything we produce, we donate to retirement homes or home care services providers that have the greatest needs, “Rydén says.

Urgent need for protective suits

Förklädesfabriken has received tremendous support from volunteers and donators, Rydén says, emphasizing the great effort of individuals.

“We have received many cries for help from elderly care service centres and home care services providers. Our volunteers have been traveling all around South Stockholm, delivering long sleeve aprons, “ Rydén says.

So far, Förklädesfabriken has produced about 35 000 protective aprons that they have delivered to about 80 retirement homes, geriatric wards and home care services providers in the South Stockholm region.

It is important to protect the elderly and the staff

Despite the huge commitment from the volunteers, Rydén believes that in a country like Sweden, we should not have to rely on voluntary efforts in order to secure the provision of protective equipment.

“But our elderly needs protection now and the professionals who are taking care of our elderly need protective equipment stryk “now”, “ he says.

Should Förklädesfabriken require more templates, Per Franson and his colleagues at KTH Royal Institute of Technology are happy to lend a hand.

“We are producing templates as long as there is a need for it. Our next step is to check the production tables and the stand on which the plastic roll is hanging, “ Franson says.

Håkan Soold