Developing nuclear fuel for future reactors

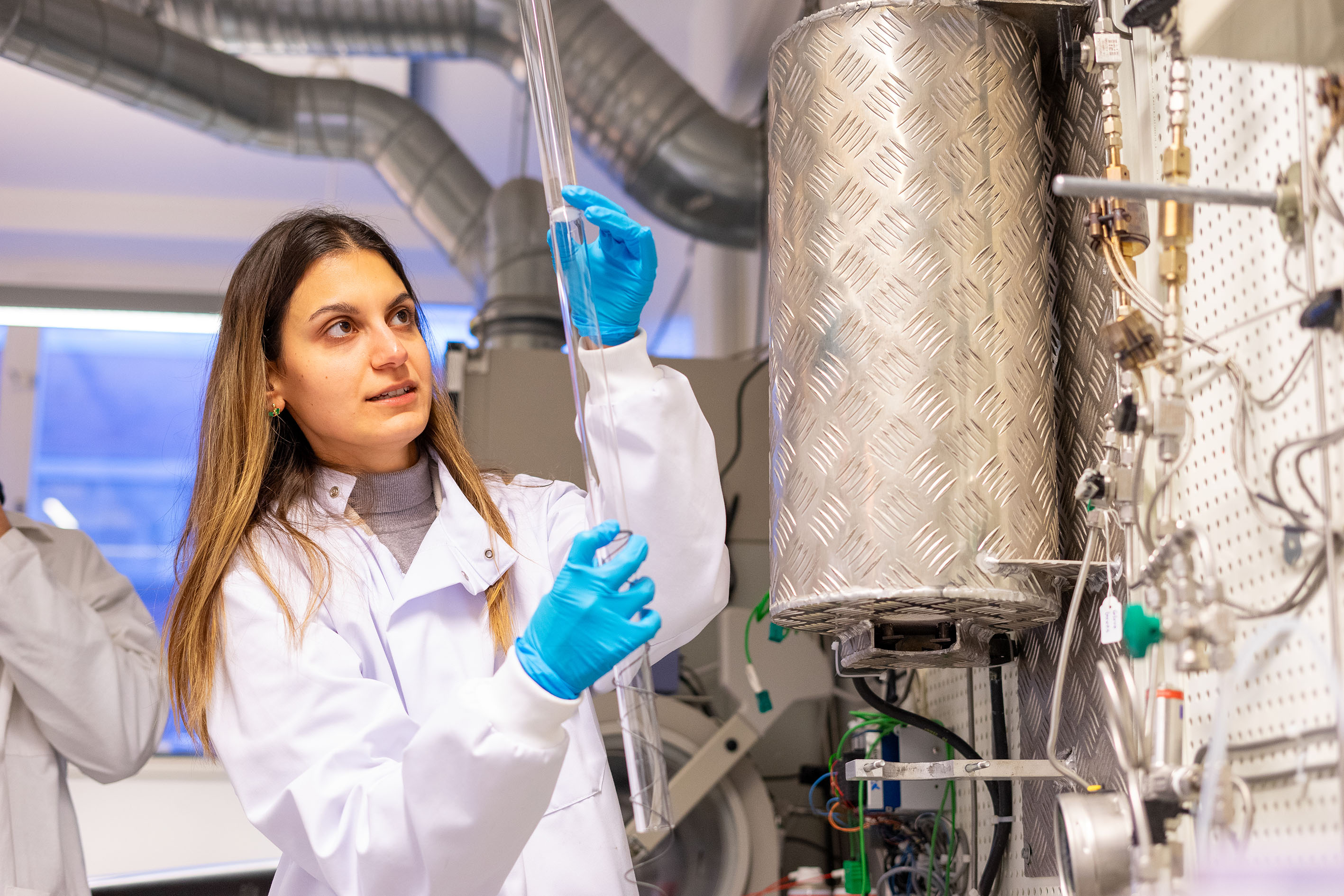

Maria Giamouridou works with a most interesting material. The PhD student is fabricating the more advanced type of nuclear fuel uranium nitride, which can be used for small modular reactors (SMR).

“The most common fuel currently used in conventional reactors is uranium dioxide (UO2). For my PhD, I perform research on uranium nitride (UN). I fabricate the fuel in the lab, starting from uranium metal and then through a process that involves three different gases, I end up with UN powder. The next step is the consolidation of the powder, through a process called Spark Plasma Sintering (SPS), which transforms the powder into a solid pellet using high current, pressure and high temperature,” says Maria Giamouridou.

“Two of the uranium dioxide pellets can be used to provide electricity for a household for a year. A single uranium pellet creates as much energy as one ton of coal.”

Why is this important?

“UN is an important fuel because it performs better than uranium dioxide. It has a higher ability to conduct heat inside the reactor than uranium dioxide and if we compare the same volume of UN to UO2, uranium nitride is 40% more dense, which means that it contains more uranium and it allows longer operation time for the reactor with less refueling. UN research started back in the 60s, but stopped since it was a difficult fuel to fabricate. It needs an inert atmosphere (non-consisting oxygen fuel), so it was more expensive and UO2 was the easy solution.”

What do you and your group hope to achieve?

“My PhD is a part of the SUNRISE project, which stands for Sustainable Nuclear Energy Research in Sweden and it is a collaboration between three different universities, KTH, Uppsala University (UU) and Luleå Tekniska University (LTU).

“The aim of the project is to build a lead-cooled research and demonstration reactor in Sweden, which will be a small reactor and a generation-IV reactor. Generation-IV reactor means that it uses coolant different than light water and, in such a case, lead. A small reactor produces power up to 300 MW and uses passive safety systems that in such cases no human intervention or external power or force is required to shut down systems, because passive systems rely on physical phenomena, such as natural circulation, convection, gravity and self-pressurization. So, each of us works on different parts of reactor components and materials to produce suitable information in order to license the reactor.”

Read more: www.kth.se/sunrise